Computer vision at the service

of a smoother, more reliable, more sustainable supply chain.

Supervise operations in real time to streamline movements, avoid bottlenecks and accelerate production rates.

Automatically detect incidents, malfunctions or anomalies so you can intervene faster and avoid downtime.

Analyze your field data to adjust resources, anticipate peaks in activity and improve overall productivity.

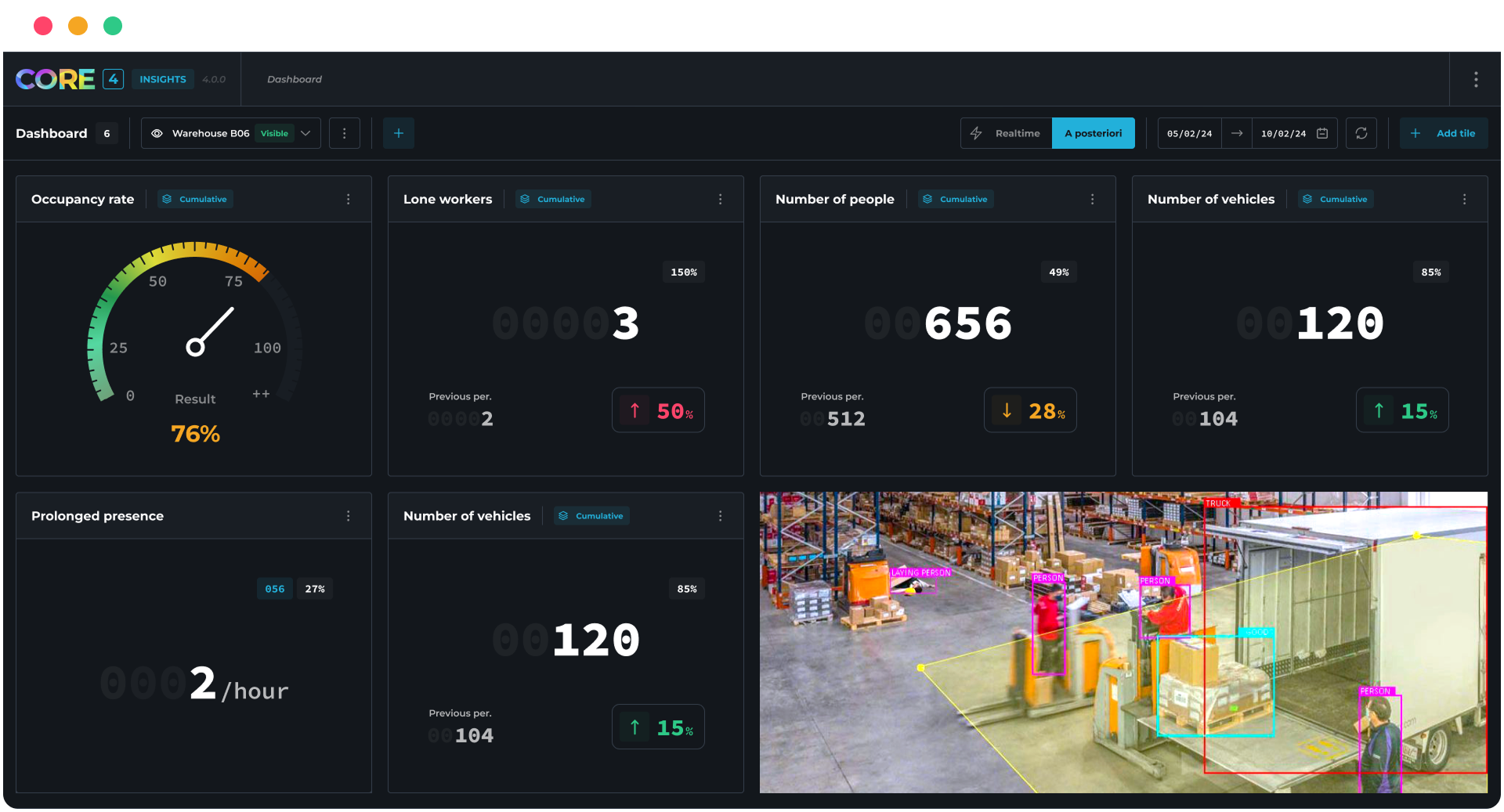

Whether you want to optimize your goods flows or secure your warehouses, visualize and analyze all logistics activities on a simple, intuitive dashboard. Access your data in real time and make the best operational decisions thanks to clear, actionable indicators.

Whether in a warehouse, logistics site or distribution hub, CORE enables you to continuously monitor your operational zones, anticipate incidents (collisions, prolonged stoppages, falls, etc.), and optimize your flows for greater productivity, safety and traceability.

Concrete uses, measurable results.

Beginning of fire detection.

Detect fire outbreaks in high-risk areas so you can intervene quickly to limit material and human damage.

Lane departure and detour.

Monitor vehicle trajectory deviations to avoid incidents and make maneuvering zones more fluid.

Obstructive parking.

Spot badly parked vehicles to clear lanes, avoid blockages and streamline logistics operations.

Automated vehicle counting.

Track incoming and outgoing vehicle flows to optimize resources and better plan operations.

Vehicle classification.

Identify the types and volumes of vehicles in circulation to better anticipate and organize flows.

Occupancy rate detection.

Measure the occupancy of storage areas in real time to adjust space usage and priorities.

Real-time fall detection.

Detect people on the ground in high-risk areas, so you can intervene quickly and keep workers safe.

Prolonged presence.

Identify objects or people who remain motionless for too long to trigger an appropriate control or alert.

Intrusion detection.

Identify any intrusion attempts in sensitive areas to prevent theft, malicious acts or incidents.

Collision detection.

Detect collisions between machines or with objects to trigger rapid intervention and limit losses.

Wearing equipment.

Check that appropriate safety equipment is consistently worn in all designated high-risk areas to ensure safety.

Isolated worker protection.

Monitor operators alone in sensitive areas to guarantee their safety and be alerted in the event of an incident.

Continuously monitor and analyze logistics zones to anticipate risks and improve operational safety.

50% fewer critical incidents thanks to automated analysis of at-risk behavior.

+40% more precise vehicle tracking.

-15% fewer delays thanks to field anomaly detection.

+20% more agility in the organization of loading zones.

Stay informed now about our products, updates and news.

![]()

Transform the physical world into data.

![]()

Ai vision software